PTFE products are manufactured - by cold compression Moulding / Sintering Process, Isostatic Moulding / Sintering process, RAM Extrusion, Paste Extrusion, Hot Coining process, Skiving process, Calendaring process & Coating process & machined to get final component.

PTFE short length Rods, Bushes & Plates are manufactured by cold compression moulding / sintering process. PTFE Resin is cold compressed / compacted in mould at around 300 kg/cm² & PTFE Resin is mechanically bonded due to its waxy nature to form product. The product is ejected from mould & then sintered in Oven at about 370°C to form rigid - chemically bonded polymerized - shape by fusion of individual PTFE particles. The product is then cooled in a controlled manner to give the moulded PTFE article.

Advantage

PTFE Products manufactured by this process have good physical properties such as Density, Tensile Strength, Compressive Strength, Hardness & Low (Low void content) permeability - longitudinally due to good compaction upto length of 300mm.

Disadvantage

PTFE Products of long, continuous length & more than 500mm & complex design are difficult to produce by this process, due to limited PTFE Resin flow properties. This manufacturing process is also quiet laborious & long duration method & also difficult to produce of lower wall thickness products.

Product

The basic shapes such as Circular & Square Rods, Bushes of heavy wall thickness upto 300mm & sheets / plates above 3mm~100mm are manufactured by this process.

PTFE long length Rods & Tubes are manufactured by Ram Extrusion Process. Ram Extrusion is a method of operating the process to produce continuous lengths of extrudate. PTFE free flow resin is continuously fed into one end of straight die tube of uniform bore, where it is compacted @ 200 kg/cm² by ram & forced along the die tube, incorporating a heated sintered zone of @ 375°C. The ram is then withdrawn, the die tube re-charged with resin & cycle repeats. In this way, the compacted powder is forced step by step through heated zone of die tube & sintered & then through cooler section, it emerges as continuous sintered PTFE Extrudate.

Advantage

PTFE products manufactured by this process are available in long lengths / continuously length upto / more than 3 meters. Recycled / Reprocessed PTFE can be processed with optimum properties very easily. As the manufacturing is continuous, the Labour cost is at minimal once the parameters are set.

Disadvantage

The physical properties such as Density, Tensile Strength, Compression Strength, Hardness, Permeability & Dielectric Strength are at minimum level due to low compression.

Product

The PTFE products of basic shapes such as Rods upto 150mm Diameter / Square, Tubes are manufactured upto 3 Meters / continuous length by this process.

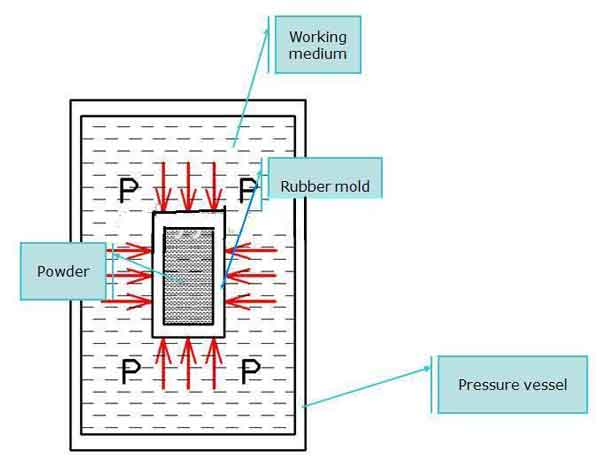

PTFE products having complex shapes are manufactured by Isostatic moulding / sintering process. The Isostatic compaction of PTFE consists of filling a flexible mould made out of Rubber / Polyurethane with Free Flow Granular PTFE Resin, closing & sealing the flexible mould, inserting this mould in a fluid contained by a Pressure Vessel, sealing the vessel & pressuring the fluid @ 350 kg/cm². The process is completed by dwelling at pressure, decompression, removal of mould from the vessel & finally removal of preformed PTFE article from the mould. The PTFE perform is then sintered in oven at @ 375 kg/cm² to effect fusion of individual PTFE particles.

Advantage

PTFE products of complex geometry are manufactured by this process. The physical properties such as Density, Tensile Strength, Compressive Strength, Hardness, Permeability & Dielectric Strength are very very superior due to uniform compression pressure from all sides. The wastage in machining is at minimum level.

Disadvantage

The machinery required is of high capital cost for this process. The process is quiet laborious, complex delicate to control & long time duration. The setting of technical parameters is quiet complex, & involves startup trial rejection.

Product

The PTFE products such as Taper Plug Valve Sleeves, Butterfly Valve Seats, Insulator Bushes for SF6 circuit breakers are manufactured by this process.

PTFE long length, flexible Tubings of thin wall sections are manufactured by Paste Extrusion Process. The process involves addition of Hydrocarbon oil to PTFE Resin to assist lubrication to extrusion. The mixture is later pressed lightly @ 25 kg/cm² into billet or performs & then forced through die of constant rate Ram Extruder. The lubricant is then removed by heating & sintered in oven @ 350°C usually in continuous long length oven inline with Paste Extrusion to form sintered tubing. PTFE un-sintered Ropes for Gasketing are also manufactured by this process & used without sintering to make use of its resilient nature.

Advantage

PTFE flexible Tubings & Liners in continuous lengths having minimum (as low as 0.5mm) wall thickness are produced.

Disadvantage

Paste Extruded PTFE forms oriented fibers, giving the extrudate high longitudinal tensile strength with virtually no transverse strength. The physical properties such as Density, Tensile Strength, Compressive Strength, Hardness, Permeability & Dielectric Strength are low & hence used for low pressure applications or within M. S. supported pipes.

Product

PTFE Flexible Tubings & Liners, Un-sintered Ropes are manufactured by this process.

PTFE products having very complex & complicated & fine design are manufactured by coining process. The coining process is carried out on PTFE sintered articles. The PTFE article, usually in gel state @ 350°C is transferred to coining die having reverse product shape & pressed at pressure @ 350 kg/cm² & cooled under pressure. The article is then ejected from mould as almost ready to use after slight finishing. The coining process is used not only to make fine adjustment to dimensions & shape, but also to change the shape radically from the original form.

Advantage

PTFE products having very complex complicated, fine designed can be produced by this process. This process is very simple & only coining die manufacture involves intricacy. The laborious machining on Conventional Lathe, Milling Machine is truly avoided by use of this process.

Disadvantage

It is the feature of Hot coined / Heat shaped PTFE products to tend to return to original shape on reheating & hence can be used upto 150°C maximum. The thermal stresses involved during coining are very high & hence changes in dimensions during the course of period are inevitable.

Product

PTFE products such as Pump Impellers, Mixer bodies, Valves & Pump, Diaphragms, Nozzles are manufactured by this process.

PTFE films & sheets of flexible nature, of continuous length / Roll form are manufactured by Skiving / Peeling process. The Skiving / Peeling process is carried out on sintered PTFE billet. The splined steel Arbor is inserted into PTFE billet & the assembly is mounted on Rotary Lathe like Skiving / Peeling Machine & rotates at @ 20-30 RPM. The cutting blade/ knife mounted on Rigid cross slide is advanced towards the billet at constant speed to peel off the continuous film / sheet of PTFE of constant thickness. The variety thicknesses ranging from 0.1mm, even upto 8mm can be peeled / skived off by increasing the speed of advancing cross slide on rotating PTFE billet / steel arbor assembly.

Advantage

PTFE films & sheets in continuous length with mini thickness of 0.1mm can be manufactured by this process with widths as wide as 3 meters

Disadvantage

The capital cost involved in machinery is quiet high. The process is quiet long, laborious & complex, particularly manufacturing thin films. The process wastage during startup & stop is quiet high, as high as 5% in the form of startup film & internal residual pipe on steel splined Arbour.

Product

PTFE films & sheets in thickness ranging from 0.1mm~8mm & width 5mm~3000mm are manufactured by this process.

PTFE un-sintered Rope manufactured by Paste Extrusion process is generally calendaring through two Roll calendaring system to form the sheet of @ 0.1mm thickness. The calendared un-sintered sheet is later slit into different widths ranging from 6mm~50mm, as un-sintered Tape. The slitting of lower widths of @ 3mm, later twisting it on twisting machine & braiding on braiding machine to form various sizes of packing's ranging from 3mm square to 25mm square is most common method of manufacturing.

Advantage

PTFE products manufactured by this process are basically for Sealing of high pressure / high temperature pipe joints, Rotary / Reciprocating / Linear Seals..

Disadvantage

This manufacturing process is quiet laborious, long duration & involves high capital investment.

Product

PTFE un-sintered Thread Seal Tape, PTFE Rope, PTFE Braided Packings / Mergollar are produced by this process.

PTFE products in moulded & extrudate form are easily machinable. All normal, high speed machining operations are carried out by tool having sharp cutting edges. PTFE products are generally machined & finished by various processes such as centre less grinding (+ 0.025), drilling @ 600 RPM, Turning & Milling @ 1000 RPM, (+ 0.05mm) to produce machined components having adequate tolerances.

Advantage

PTFE machined products can be provided on conventional machines such as Centre Lathe, Milling Machine, Drilling Machine, Centre-less Grinding Machine with no special attachments or special technology with low capital cost.

Disadvantage

Due care has to be taken such as coolant spraying, Temperature controlled workshop etc while machining & measurement of PTFE component as dimensional / Linear change as high as 1% takes place between 0 to 100°C. Hence, machining / measurement within close tolerances has to be done taking care of this / coefficient of thermal expansion

Product

PTFE Valve Seats, PTFE Gaskets, PTFE Bellows / Expansion Joints, PTFE Balls, PTFE 'O' Rings are produced by this process.

PTFE products in moulded & extruded sections are chemically treated by Sodium Itching to make the surface of PTFE bondable. The itchant generally solution of Alkali metal solution as complex with Naphthalene in Tetrahydrofurane is used for surface treatment. PTFE products are immersed in itchant to change the colour of PTFE surface from white to metallic brown, the shade darkening with increased immersion time. After treatment, PTFE products are removed from solution & residual itchant is removed by washing with alcohol & later by washing in warm water. Once itched state is achieved the surface of PTFE is no longer "non-stick" & becomes bondable with vide range of adhesives. The adhesives used are generally two component Epoxy system such as Loctite.

Advantage

PTFE products are antistatic & no adhesive can be used to stick them. By sodium itching / chemical treatment - surface of PTFE product became bondable & almost all epoxy based two component adhesive can be used to glue / adhere PTFE product to any substrate such as Plastics, Metals & Non-metals.

Disadvantage

Manufacturing of itchant application of itchant to PTFE & later disposal - is highly hazardous process due to volatile nature of alkali sodium metal. The high degree of health safety & fire precaution need to be maintained during this process. The itched surfaces of PTFE are weakened by ultraviolet component of daylight & thus have limited shelf life. Hence, chemically treated PTFE Product may be used immediately after itching or may be kept in dark or wrapped in black plastics sheets / bags. Due to application of adhesive, the limiting service conditions such as Temperature, Chemical resistance, flexibility etc are on the basis of properties of adhesive. The thermal resistance of itch is around 150°C & may weaken the bond beyond this temperature.

Product

PTFE products such as Diaphragm sheet, Insulator Rings, Gaskets, Bridge Bearing Pads are generally sodium itched for adhering to base structure such as Rubber, Metals & Non-metals.

Products manufactured by PTFE coating process are basically for non-stick applications. Generally mild steel, stainless steel & other nonferrous articles are surface treated such as shot blasting, polishing & sprayed PTFE aqueous solution by Air / Pneumatic spray gun. These articles then air-dryed & put inside oven for sintering & bonding of coated PTFE layer of max 0.2mm @ 300°C. The articles are cooled slowly to avoid any rapture of coated layer.

Advantage

The manufacturing process is very simple & low cost. Complete automation by Robotics can be arranged for mass production of PTFE coated products. Large, intricate & complex parts can be easily coated by this process.

Disadvantage

Due to coating involves spray mechanism, the coated surface is generally micro-porous having low permeability resistance. Due to varied coefficient of Thermal Expansion of PTFE coating & substrate, the PTFE coating tends to rupture / separate from substrate above 150°C.

Product

PTFE coated lab ware, Utensils, Textile Rollers, Printing Machine Rollers & cloth irons base are most commonly manufactured products by this process.