Hindustan Nylons manufacturers Trexonn slideway Liners to greatly upgraded conventional Machine Tools, CNC Machine & Hydraulic Machines for Machine tool holders, Re-builders & machine maintenance imparting unique working advantages leading total quality & maximum productivity.

Hindustan Nylons manufacturers Trexonn slideway Liners to greatly upgraded conventional Machine Tools, CNC Machine & Hydraulic Machines for Machine tool holders, Re-builders & machine maintenance imparting unique working advantages leading total quality & maximum productivity.

Hindustan Nylons is company with difference.It is new, but the expertise it possesses is not.At the core of company are people,who have knowledge &experience of all aspects of FLUOROMETALS be it engineering & design manufacture, application or serving.

We firmly believe on developing new systems to greatly upgrade the conventional systems imparting TOTAL QUALITY & MAXIMUM PRODUCTIVITY.

This is what, we have under taken for Machine Tools Manufacturers, Rebuilders,by devotionof skills & efforts.

The result is TREXONN BEARING SYSTEM, essential for your Machine Tools.

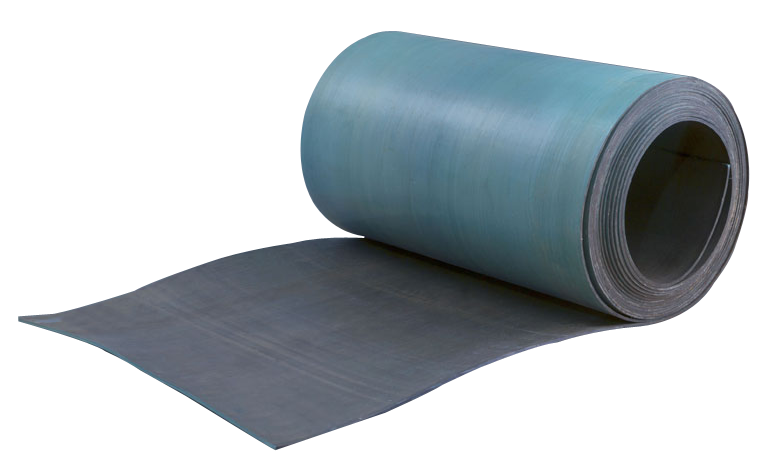

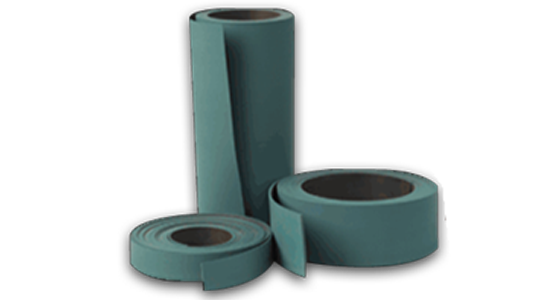

The TREXONN GLYDVEL Linear Bearing System is employed on Machine Tools,Transfer Lines for achieving Total Quality & Maxmimum Productivity.The system basically consists of Trexonn Fluromentalic Linear fixed on moving part of Machine Tools VIZ, Slideways and this sliding part of Machine Tools moves over guideways, avoiding direct metal to metal contact,

The system imparts unique working advantages, due to outstanding properties of TREXONN

TREXONN Is Fluoromental, which is extensively used in Machanical,Machine Tool Manufacturing Industries, Hydraulics & Pneumatics Manufacturing Industries due to its unique characteristics.

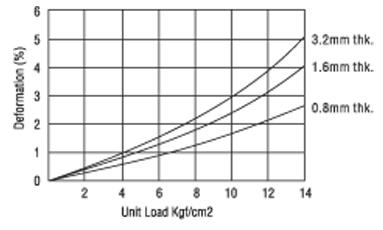

TREXONN-GLYDVEL Linear Bearing System is available with forms of liners in different thickness 0.75mm, 1.25mm, 1.5mm, 2.5mm, 3mm & standard width of 305mm.

* Non standard forms available on requestThe TREXONN GLYDVEL Liner has been chemically treated on one side & is ready for adhering to the correctly prepared metallic surface.

2.Prepration of Metallic Surface

The metallic surface & TREXONN liner may be exposed to air for minutes for accelerating the curing & subsequently the TREXONN liner may be kept on metallic surface from one end & then slowly upto other end

5.CuringDuring curing the constant clamping pressure of 200gm/cm2 may applied for 48 hours

6.FinishingAfter curing TREXONN liner can be finished by conventional finishing mediums like Grindstone & Polish papers

| Grind Stone | Grinding Medium | SIC |

|---|---|---|

| Grain Size | 46 | |

| Roughness | G | |

| Structure | 16 | |

| Binder | Ke | |

| Polish Papers | Medium | Electrocoated SIC Grain Size |

| Binder | 240 | |

| Roughness | p |

The Best performance of TREXONN systems is dependent on bonding strength between metallic surface & liner. Hence any deviation w.r.t.undernoted matter shall result in poor bonding & leading to premature failure of total system.

| Property | Unit | Test Method | Value |

|---|---|---|---|

| Density | gm/cc | ASTM-D-792 | 3.2(Min.) |

| Tensile Strength | kgf/cm2 | ASTM-D-638 | 150(Min.) |

| Elongation | % | ASTM-0-638 | 150(Min.) |

| Compressive Strength | kgf/cm2 | ASTM-D-695 | 100(Min.) |

| Heat Resistance | °C | ASTM-0-648 | -250 to +250 °C |

| Hardness | ShoreD | ASTM-D-2240 | 64(Min.) |

| LimitingPVValue | kgf/cm2x mm/s | Type | 400(Min.) |