The exact manner in which the fabrication of the polymer is carried out affects certain intrinsic qualities in the polymer which, in turn, influence some properties, notably tensile strength, elongation and dielectric strength. The intrinsic qualities of PTFE which can be affected by fabrication conditions are molecular weight, crystallinity, orientation and the presence or otherwise of voids and interfaces. These factors will now be considered in turn.

All commercial samples of PTFE (with the exception of lubricant powders) are of extremely high molecular weight; granular polymers are of somewhat higher molecular weight than dispersion polymers. Because of its insolubility, the molecular weight of PTFE can be measured only with difficulty.

The best method of assessing the molecular weight of PTFE is undoubtedly by measuring the viscosity of the polymer at some temperature above its melting point. This approach demands, however, some fairly sophisticated equipment if it is to be successful and less direct methods of arriving at an idea of molecular weight are often favoured.

When PTFE is cooled from a temperature above its melting point at a carefully controlled rate, the extent to which the polymer crystallises will be inversely dependent on the molecular weight. Now, assuming the moulding contains no voids, its crystallinity can be inferred from its relative density, so the relative density of a moulding prepared under precisely defined conditions (this quantity is often called the standard relative density) can be used as an index of molecular weight. The relationship:

standard relative density = 2.612-0.058 log10Mn

has been given where weight Mn is the number average molecular weight .

The thermal stability of PTFE is so great that, if processed correctly, the polymer should suffer no significant degradation and the molecular weight of the finished product will be determined almost entirely by that of the raw polymer.

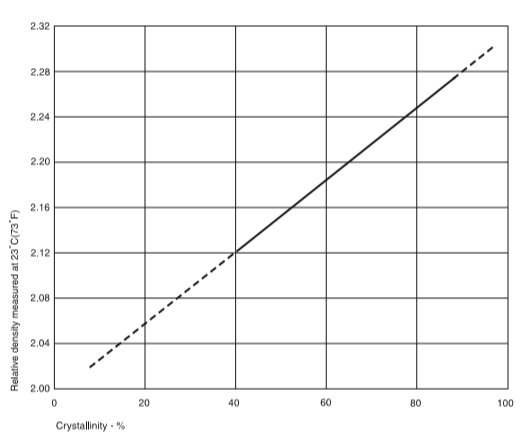

As polymerised, PTFE is of 90-95% crystallinity but when it is heated above its crystalline melting point the polymer becomes amorphous. In the melt state PTFE does retain some two-dimensional order but, as the three dimensional crystal structure has been destroyed, molten PTFE can properly be thought of as amorphous. On cooling, the extent to which crystallisation occurs is dependent both on the molecular weight of the polymer and on the rate of cooling, particularly at temperatures just below the melting point. Slow cooling naturally tends to increase the extent of crystallisation. Almost all fabricated PTFE displays crystallinities within the range 50 to 75% depending on the rate of cooling. The crystallinity of PTFE is best measured by X-ray diffraction or by infra-red absorption methods These respectively assess ‘order’ and ‘disorder’ within the specimen. However as the relative density of 100% crystalline PTFE at 23°C (73°F) is 2.30 while that of 0% crystalline (100% amorphous) PTFE under the same conditions is 2.00, the relative density of PTFE can be used to give a simple index of crystallinity. Clearly it is essential that the specimens used for relative density measurements be free from voids and, since such voids are less likely to occur in specimens produced from coagulated dispersion polymers, the technique is probably of greater value in this field than in that of granular polymers. The relationship between relative density and crystallinity for void-free specimens of PTFE is shown in Figure 8. The level of crystallinity in fabricated PTFE is a matter of considerable importance. In general, fabricators attempt to keep the crystallinity to a minimum as the higher the amorphous content the greater the ultimate tensile strength and the longer the flex life will be. In some instances, however, such as where gas permeability must be reduced, higher crystallinities will be desirable.

The orientation of PTFE is a measure of the extent to which the polymer chains are aligned in any particular direction. This alignment, because of their methods of processing, is more likely to occur with the coagulated dispersion polymers than with the granular or aqueous dispersion materials.

During fabrication, PTFE does not pass through the state of being a low viscosity liquid and, as a result, articles made from PTFE may possess voids and interfaces in the mass of the polymer. These faults are more likely to occur in large articles made from granular polymers than in articles of thin cross-section made from either aqueous or coagulated dispersion polymers. The problem of voids in granular mouldings can almost always be overcome by careful choice of the correct granular polymer for a particular duty and by use of the appropriate fabrication technique. For practical purposes the absence of voids in fabricated PTFE is denoted by good tensile strength, high elongation at break, low gas permeability, prolonged flex life and high dielectric strength. It is often possible to detect voids by examining a thin section - preferably less than 0.25 mm (0.01 inch) - by transmitted light when a sample free from voids will be translucent with a faintly blue colour. On the other hand a sample containing many voids will be white and opaque with a chalky appearance. If the sample is first treated with a penetrant dye† then the detection of voids is made a great deal easier.

† Such as ‘Ardrox’ 996P supplied in the UK by Chemetall plc, 65

Denbigh Road, Bletchley, Milton Keynes, MK1 1PB (UK)

Tel. +44 (0) 1908 649333 Fax +44 (0) 1908 361872

www.aerospace.chemetall.com

in mid-Europe by Chemetall GmbH, Frankfurt a.M. Tel. +49 (0) 697165-0

and in the USA by Chemetall Oakite, 50 Valley Road, N.J. 07922,

Berkeley Heights

Tel. +1 908 508 2214 Fax +1 908 464 7914 Toll-free 800 526 4473

www.oakite.com